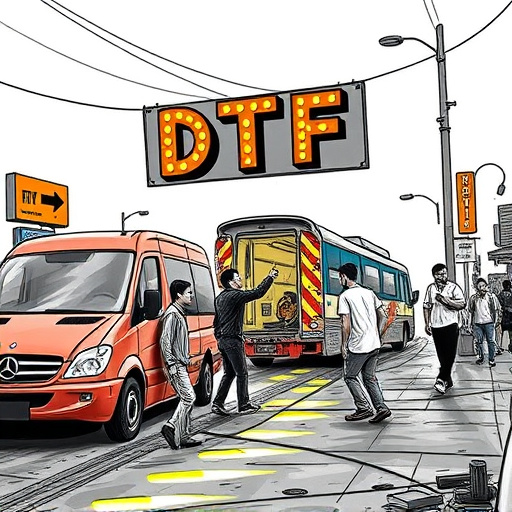

Direct-to-Film (DTF) transfer is a cutting-edge printing technique that eliminates traditional steps by directly applying ink to film surfaces, offering exceptional detail retention and vibrant color reproduction. This method enables effortless application of designs to various materials, accelerates turnaround times, and caters to diverse clients from photographers to event organizers. The booming DTF market meets the demands of customizable, high-quality printing driven by e-commerce and fast fashion trends, with evolving consumer preferences for personalized products fueling its growth. The production process involves artistic conception, digital illustration, precision printing, quality control, cutting, and weeding, resulting in long-lasting, detailed prints on diverse film types. DTF transfers streamline production, offer competitive pricing, and enhance brand identity, while future innovations promise expanded applications and personalization across various media.

In the dynamic realm of printing, Direct-to-Film (DTF) transfer has emerged as a game-changer. This innovative method allows businesses to produce high-quality, durable prints on various surfaces directly from digital files, revolutionizing everything from apparel design to signage. This article delves into the world of DTF transfer, exploring its understanding, business models, market trends, production processes, benefits, and future innovations. By embracing this cutting-edge technology, businesses can stay ahead in a competitive landscape, driven by growing demand for versatile DTF transfer solutions.

- Understanding Direct-to-Film (DTF) Transfer: A Revolutionary Print Method

- The Business Model: Specializing in DTF Transfer Products

- Market Trends and Demand for DTF Transfer Solutions

- Production Process: From Design to Final Product

- Benefits and Applications of DTF Transfer Technologies

- Future Prospects and Innovations in the DTF Transfer Industry

Understanding Direct-to-Film (DTF) Transfer: A Revolutionary Print Method

Direct-to-Film (DTF) transfer is an innovative printing technique that has revolutionized the way we produce high-quality images and graphics. This method involves transferring ink directly onto a film surface, eliminating the need for traditional intermediate steps. With DTF, designs can be effortlessly applied to various materials, from vinyl cut-outs to fabric and more, making it a versatile choice for businesses catering to diverse industries.

The process begins with creating or obtaining a digital design that is then precisely printed onto a film using specialized equipment. This film acts as a reusable master, allowing for accurate and consistent transfers across different media. DTF offers exceptional detail retention, vibrant color reproduction, and the ability to produce complex designs without compromise. It’s a game-changer for custom printing, enabling businesses to offer fast turnaround times, on-demand production, and a high degree of design flexibility, thus catering to the ever-growing demands of modern consumers.

The Business Model: Specializing in DTF Transfer Products

In today’s digital age, businesses specializing in direct-to-film (DTF) transfer products are revolutionizing the printing industry. This innovative business model focuses on creating high-quality, precise prints by transferring images directly onto various film surfaces. By eliminating traditional intermediates, DTF transfer offers a cost-effective and efficient solution for both commercial and personal applications.

The specialization in DTF transfer products allows businesses to cater to a diverse range of clients, from photographers and artists to marketing agencies and event organizers. This niche market approach ensures that each customer’s unique requirements are met with customized solutions. Advanced technologies and precision engineering enable these companies to produce vibrant, detailed prints, ensuring customer satisfaction and fostering long-term relationships.

Market Trends and Demand for DTF Transfer Solutions

The market for direct-to-film (DTF) transfer products is experiencing significant growth, driven by several key trends. One of the primary factors is the increasing demand for high-quality, customizable printing solutions across various industries, from apparel to signage. DTF transfers offer a cost-effective and versatile method of applying designs to a wide range of materials, appealing to both small businesses and large enterprises.

Additionally, the rise of e-commerce and fast fashion has accelerated the need for efficient and rapid production methods. DTF technology allows for quick turnaround times, enabling businesses to meet the demanding schedules of modern retail. As consumer preferences continue to evolve, the market is witnessing a growing appetite for unique, personalized products, further fueling the demand for DTF transfer solutions that can accommodate intricate designs and diverse material applications.

Production Process: From Design to Final Product

The production process for direct-to-film (DTF) transfer products is a meticulously crafted journey, transforming initial designs into tangible final products. It all begins with artistic conception and technical translation. Designers and artists work hand in hand to create visually stunning artwork, ensuring it aligns with client requirements. This design phase involves intricate digital illustration, where every detail is carefully considered for optimal reproduction on various film surfaces.

Once the design is finalized, it undergoes a series of precision printing steps. Advanced printing technologies enable the transfer of these designs onto films, be it vinyl or other specialized materials. The printed films are then carefully examined to guarantee accuracy and quality. After quality control, the films are ready for cutting and weeding, where excess material is meticulously removed, leaving only the desired design elements intact. This meticulous process ensures that when the film is applied to a surface, it creates a vibrant, long-lasting DTF transfer with exceptional clarity and detail.

Benefits and Applications of DTF Transfer Technologies

Direct-to-film (DTF) transfer technologies offer a range of benefits and versatile applications in various industries. One of its key advantages is the ability to produce high-quality, full-color prints directly on different types of films, eliminating the need for intermediate steps. This streamlined process reduces production time and costs, making it an efficient choice for businesses seeking fast turnaround times without compromising on visual appeal.

DTF transfer is particularly valuable in fields like packaging, signage, and even fashion. It enables manufacturers to create custom, visually stunning designs for product packaging, outdoor advertisements, and clothing labels. The technology’s precision allows for intricate details and vibrant colors, ensuring brand identity and marketing messages are effectively conveyed. Additionally, DTF transfers can be applied to various materials, opening up endless possibilities for innovative product designs and promotions.

Future Prospects and Innovations in the DTF Transfer Industry

The future of direct-to-film (DTF) transfer products looks promising, with continuous innovations pushing the boundaries of what’s possible in the industry. Emerging technologies such as advanced printing methods and high-quality materials are enhancing the accuracy and durability of DTF transfers, making them suitable for a wider range of applications. This evolution is particularly exciting for businesses specializing in custom designs, enabling them to offer more intricate and personalized products at competitive prices.

Additionally, the increasing demand for unique, on-demand products is driving innovation in DTF transfer technology. As consumers seek more individualized options, manufacturers are responding with versatile systems capable of producing high-resolution prints on various media types. This trend suggests a future where DTF transfers play an even more significant role in personalizing and enhancing everyday objects, from fashion accessories to home décor items, offering endless creative possibilities for businesses and consumers alike.