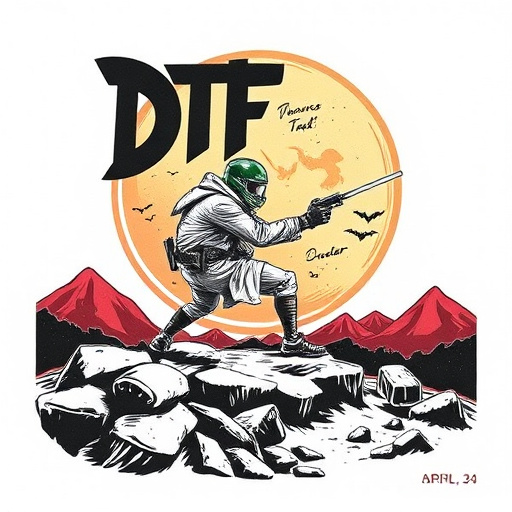

Direct-to-Film (DTF) prints are transforming screen printing by enabling high-quality, digital graphics on diverse surfaces for small batches and on-demand projects. With fast turnaround times, vibrant colors, and intricate designs, DTF is ideal for custom merchandise, signage, and short-run products. This technology benefits SMEs, large corporations, event planners, and artists, revolutionizing industries like automotive, textiles, and entertainment. Showcase the advantages of DTF through online platforms, collaborate with influencers, and adopt sustainable materials to stay competitive in a growing market focused on innovation.

“Direct-to-film (DTF) printing is revolutionizing the screen printing industry, offering a unique and efficient approach to creating high-quality custom designs. This specialized business focuses on producing DTF transfer products, catering to a diverse range of customers seeking innovative branding solutions. From understanding the intricacies of DTF prints to exploring future trends, this article delves into the world of direct-to-film technology, providing insights into its benefits, production processes, and marketing strategies that set these businesses apart in the competitive custom print market.”

- Understanding Direct-to-Film (DTF) Prints: A Unique Approach to Screen Printing

- The Benefits of Specializing in DTF Transfer Products

- Target Market and Customer Base for DTF Print Businesses

- Production Process: From Design to Final Product

- Marketing Strategies for Standing Out in the Custom Print Industry

- Future Trends and Innovations in DTF Printing Technology

Understanding Direct-to-Film (DTF) Prints: A Unique Approach to Screen Printing

Direct-to-Film (DTF) prints represent a groundbreaking approach within the screen printing industry, offering a unique and efficient method for producing high-quality graphics on various materials. This innovative technique bypasses traditional screen preparation steps, allowing designers to print directly onto film or other suitable surfaces. With DTF, images are transferred from a digital file to the desired medium using specialized equipment, ensuring precision and speed.

Compared to conventional screen printing methods, DTF Prints offer several advantages. They eliminate the need for setting up screens, making them cost-effective for small batch productions and on-demand printing. This process is particularly useful for businesses specializing in custom merchandise, signage, or short-run projects, as it provides quick turnaround times and flexibility. Additionally, DTF technology enables the creation of intricate designs with vibrant colors, making it a favorite among artists and brands seeking exceptional visual impact.

The Benefits of Specializing in DTF Transfer Products

Specializing in direct-to-film (DTF) transfer products offers a range of benefits for businesses, particularly in the printing and manufacturing sectors. DTF prints provide an innovative and efficient solution for creating high-quality, long-lasting images on various materials, such as plastics, metals, and fabrics. This specialization allows companies to tap into a growing demand from industries like automotive, signage, and textiles, where durable and precise graphics are essential.

With DTF technology, businesses can offer fast turnaround times without compromising on quality. The process eliminates the need for expensive set-up costs associated with traditional printing methods, making it a cost-effective choice. Moreover, DTF transfers enable the production of intricate designs with vibrant colors and sharp details, ensuring customer satisfaction and fostering strong brand associations. This specialization positions businesses as leaders in their field, attracting clients seeking cutting-edge solutions for their marketing and product development needs.

Target Market and Customer Base for DTF Print Businesses

The target market for Direct-to-Film (DTF) print businesses is diverse and spans across various sectors, each with unique needs and applications. These businesses cater to a broad customer base, including small and medium-sized enterprises (SMEs), large corporations, event organizers, and individual enthusiasts. SMEs often seek cost-effective solutions for short-run or custom printing projects, making DTF prints an attractive option due to their speed and versatility. Large companies may utilize DTF technology for specific marketing campaigns or product branding.

Event planners and promoters are another significant segment, embracing DTF prints for creating promotional items like personalized banners, posters, and merchandise at festivals, concerts, and conferences. Individuals who engage in creative pursuits, such as artists and hobbyists, also benefit from this technology for printing custom art, photos, or designs on various media, expanding their artistic expressions.

Production Process: From Design to Final Product

The production process for direct-to-film (DTF) prints involves a meticulous journey from design conception to the final product. It begins with graphic designers creating digital artwork, meticulously crafting each element to ensure it translates accurately onto the chosen film medium. This design phase is crucial in determining the overall aesthetic and functionality of the end product.

Once approved, the design files are prepared for printing. The artwork is then digitally transferred onto a transparent film, precisely aligning colors and details. After quality checks, the film is fed into specialized printing machines that use advanced technologies like inkjet or laser printing to reproduce the designs in high resolution. The printed films are then carefully cured or treated to ensure longevity and durability. Finally, these films are packaged and prepared for distribution, ready to be applied to various surfaces, transforming blank canvases into captivating visuals.

Marketing Strategies for Standing Out in the Custom Print Industry

In the competitive landscape of custom print services, standing out as a business specializing in direct-to-film (DTF) prints requires a strategic marketing approach. One effective strategy is to showcase the unique benefits and applications of DTF Prints. Highlight how this technology offers vibrant, high-quality results, especially for films, animations, and visual effects in the entertainment industry. Emphasize the speed and efficiency of the process, appealing to clients seeking fast turnaround times without compromising on quality.

Leverage online platforms and social media to reach a broader audience. Create engaging content that demonstrates your expertise, such as behind-the-scenes videos, client testimonials, and tutorials explaining DTF printing processes. Collaborate with industry influencers or relevant brands to expand your reach. Offer exclusive discounts or promotions targeted at specific niches within the custom print market to attract new customers and build a loyal client base.

Future Trends and Innovations in DTF Printing Technology

The future of Direct-to-Film (DTF) printing technology looks promising, with innovations set to revolutionize the industry. One prominent trend is the shift towards more sustainable and eco-friendly materials and processes. As environmental consciousness grows, businesses are exploring water-based inks and biodegradable films, reducing the industry’s carbon footprint without compromising quality. Additionally, advancements in print head technology promise faster processing times and improved resolution, making DTF prints even more versatile for various applications, from packaging to signage.

Another exciting development is the integration of smart materials and digital connectivity. By incorporating sensors and interactive elements into DTF prints, businesses can create dynamic and responsive products. This could include everything from adaptive clothing that changes color based on temperature to interactive marketing displays that offer enhanced customer engagement. With these innovations, DTF printing technology is poised to not only meet the demands of today’s markets but also anticipate and shape tomorrow’s trends in packaging, fashion, and beyond.